Effect of Squeeze Casting Parameters on Tensile Strength and Hardness of Aluminum Cast Part

DOI:

https://doi.org/10.60787/ijtec.vol1no1.31Keywords:

Squeeze casting, mould temperature, pouring temperature, tensile strength, hardnessAbstract

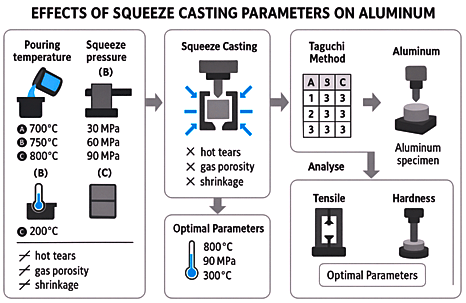

Over the years, researchers have grown increasingly interested in how squeeze casting settings such as pouring temperature, squeeze pressure, and mould temperature influence the tensile strength and hardness of aluminium castings. Squeeze casting which forces metal into a die under high pressure cools more quickly than standard methods thus reducing defects such as hot tears, gas porosity, and shrinkage. To address these issues, this study uses the Taguchi statistical technique with an L9 orthogonal array, assigning three levels to each of the three factors: mould temperature (A) at 2000C, 2500C and 3000C; pouring temperature (B) at 7000C, 7500C and 8000C; and squeeze pressure (C) at 30, 60 and 90 MPa. Eighteen (18) aluminum specimens were produced from recycled aluminium scrap by repeating each trial twice for accuracy. Castings were tested for average tensile strength and hardness after standard machining to remove surface irregularities. The result showed that the combination of 90 MPa pressure, 8000C pouring temperature and 3000C mould temperature yield the strongest mechanical properties. The experimental result also shows that, squeeze pressure had the most significant impact on both tensile strength and hardness. Additional analysis of the signal-to-noise ratio substantiated this ranking and guided the optimal hardness of 90 MPa squeeze pressure, 800°C pouring temperature, and 300°C mould temperature. These findings demonstrate that careful control and optimization of squeeze casting parameters can significantly improve the quality and performance of aluminum cast products.

Downloads

Downloads

Published

Issue

Section

License

Copyright (c) 2025 International Journal of Tropical Engineering and Computing

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.